Wind energy, as an auxiliary power source for ocean-going vessels, has been widely promoted and applied worldwide. Many shipowners have installed wind energy auxiliary power devices in their fleets to achieve the effects of green decarbonization and cost savings. There are mainly four mainstream research and development directions for wind-assisted power systems, namely, rotary cylinder sails, hard-wing sails/plate sails, kite sails and inflatable wing sails.

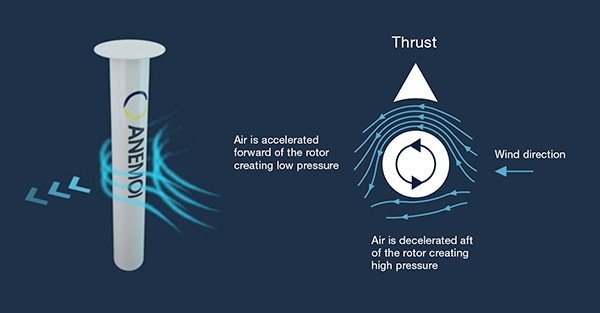

Rotary tube sails, as a tool to enhance ship performance and reduce carbon emissions, are constantly attracting the interest and attention of the shipping industry. It generates a force perpendicular to the wind speed by driving the cylinder to rotate in the wind, providing a thrust for the hull to move forward.

Compared with other wind-driven devices, the rotary sail made of composite materials is lighter, more flexible and has a wider range of applications. It can be installed on various types of ships with open deck areas, such as bulk carriers, oil tankers, passenger ships and roll-on/roll-off ships. Depending on the size and number of helical sails installed on a single vessel, the average fuel savings can reach 5-25%. Therefore, the energy-saving effect and economic efficiency of the rotary cylinder sail are outstanding, not to mention the additional benefits such as the carbon tax value generated after reducing CO2 emissions.

SWANCOR HYVER 2250 is a free radical modified room-temperature curing epoxy resin, which is particularly used in the processing of wind turbine blades, boats and large structural products, and has passed DNV and CCS certifications. Its main features include low viscosity, room-temperature curing ability, low shrinkage rate, excellent adhesion to UP gel coat, and good impregnation effect on glass fiber and carbon fiber.

SWANCOR HYVER 2250 contains the main agent, curing agent and initiator. It features a composite crosslinking system. By introducing a free radical system into the existing epoxy curing system, an interlocking network structure is generated, endowing the material with both the toughness of an epoxy system and the rigidity of a free radical system. The advantages of SWANCOR HYVER: 1. Under the same conditions, the mechanical properties of SWANCOR HYVER products are excellent and comparable to those of traditional epoxy resin products. 2. SWANCOR HYVER does not require any changes to the existing epoxy material system or the current process, and it has strong process adaptability. Compared with epoxy, SWANCOR HYVER can cure at room temperature and has the property of hardening at room temperature.

Currently, the SWANCOR HYVER free radical modified epoxy resin from Swancor has been successfully applied to rotary drum sails, and the sails made with SWANCOR HYVER have passed all the certifications of classification societies. Domestic manufacturers of rotary drum sails, represented by Diefeng New Energy Technology (Tianjin) Co., LTD. (" Diefeng Technology "), are in a leading position in China. Diefeng Technology holds over 20 patents for rotary drum sails with independent intellectual property rights and is capable of manufacturing wind-assisted propulsion equipment such as 24-meter × 4-meter rotary drum sails and 35-meter × 5-meter rotary drum sails. Meanwhile, the company is innovatively developing 10-meter by 2-meter rotary cylinder sails suitable for installation on smaller vessels along China's coast, in order to reduce installation costs and meet the demands of numerous small and medium-sized shipowners in China. The rotary cylinder sails of Diefeng Technology have been certified by Lloyd's Register, Japan Classification Society and China Classification Society, and can provide shipowners with one-stop services including the installation of new ships or the design, modification and installation of old ships. The rotary cylinder sails of Diefeng Technology have a small scope of modification for ships. They do not require docking and can be carried out at the dock, with a modification cycle as short as 7 to 15 days. Moreover, there are various forms such as fixed type, tiltable type and track type for different ship types to choose from. It utilizes wind energy to assist in the propulsion of ships, achieving a fuel-saving effect of 10% to 20%, and the equipment investment payback period is only 2 to 4 years. Compared with the two largest foreign manufacturers of rotary sails, Norsepower and Anemoi, the rotary sails of Diefeng Technology have a significant advantage in terms of cost performance and are an excellent choice for domestic substitution.